Request More Info

Here at Tec Container Asia Pacific we are specialists in designing and manufacturing container spreaders. Backed by over 35 years experience delivering spreaders on a global scale, we can find the perfect cargo / container spreader for you.

Not only are we experts in creating customised solutions to suit your lifting needs, we’re renowned for manufacturing equipment that delivers efficiency and reliability. What’s more, our container spreaders and container handling equipment are of premium quality at an affordable price point. As a result, the productivity of your port, terminal or factory area is optimised, reducing down time, delays and negative impact on your bottom line.

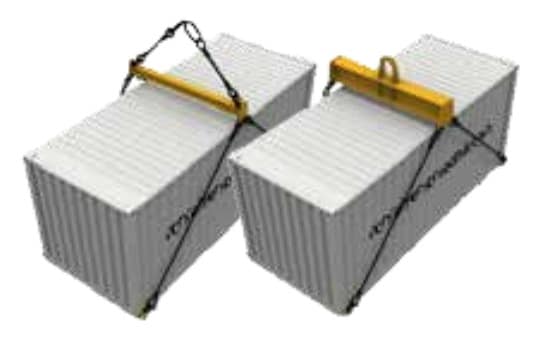

Our cargo spreaders are the safest solution for container handling, making your work simpler and more profitable. Every cargo spreader is designed and manufactured in compliance with relevant safety regulations. Above all, we understand that reliable, compliant equipment is of utmost importance to the smooth operation of your freight handling location.

Semi Automatic Spreaders

BA-350S

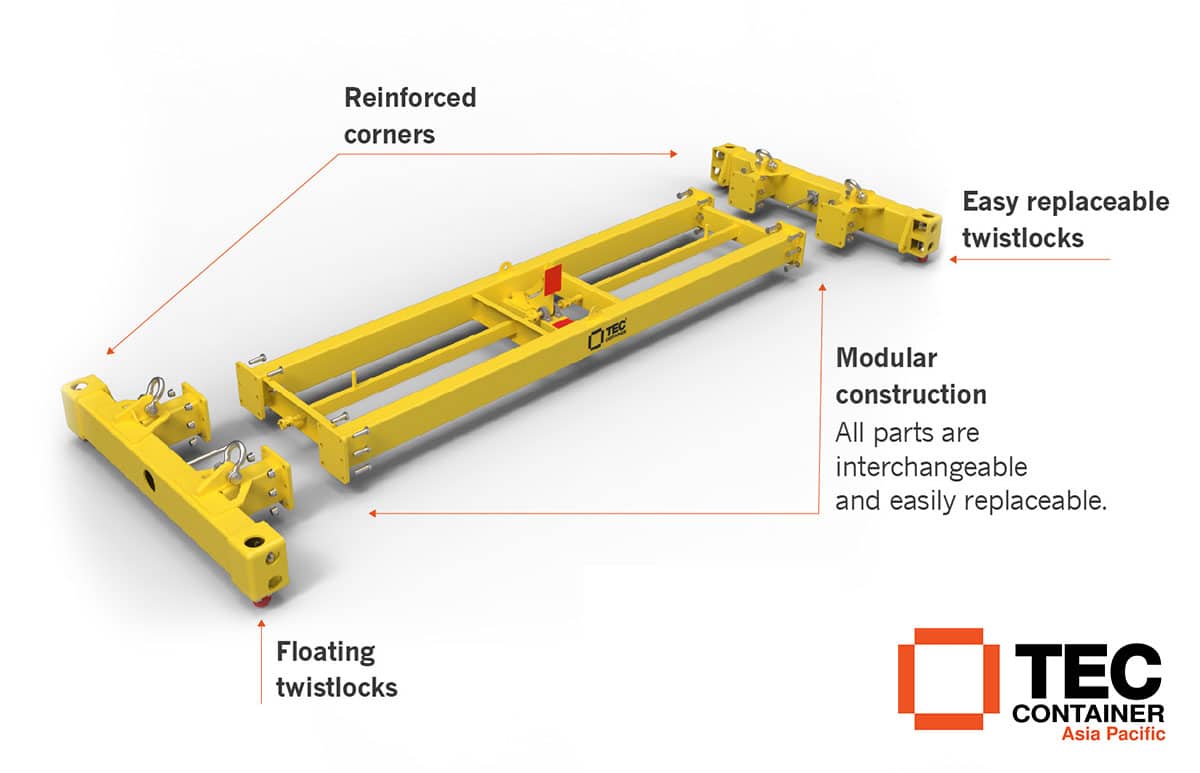

At Tec Container, we never stop innovating. We are introducing the BA-350S semi-automatic spreader:

Features:

- Newly designed floating twist-locks that can be easily removed and replaced when they are damaged

- Modular construction: spreader heads are removable and interchangeable, thus making the replacement much easier than ever before

- The corners of the spreader have been enhanced and reinforced

The new BA-350S semi-automatic container spreader is ideal for any port/container terminals, stevedoring companies and crane operators etc. It comes in as 20-foot (SWL 32T, 36T) and 40-foot (SWL 40T) variants. The container spreader is equipped with high-quality components that are made of the best materials in the market, ensuring its long durability and reliability during its entire life span.

Please check out this video showing this spreader in operation: https://vimeo.com/460112319

Technical Specs:

- WLL 32T for the 20ft spreader, customisable to 36T

- WLL 40T for the 40ft spreader

- Customisable sizes available: 10ft and 45ft

- Safety landing pins

- Colour and logo upon customer request

Contact our team today for a competitive pricing on our new BA-350S spreaders:

Fully Electric Spreaders

BA-350E

This Fully automatic and remote controlled – fixed length – spreader for Containers is standard available in 20′ and 40′ and due to its modulare design can be produced in other sizes.

Features:

- Twistlocks are FULLY AUTOMATIC BY REMOTE CONTROL

- Twistlock are fully electric battery operated, so no hydraulics and are equiped of Safety interlocking pins so no intermediate twistlock positions with yellow/red/green light feedback of the twistlock positions

- Modular construction: spreader heads are removable and interchangeable, thus making the replacement much easier than ever before

- The corners of the spreader have been enhanced and reinforced

The new BA-350S semi-automatic container spreader is ideal for any port/container terminals, stevedoring companies and crane operators etc. It comes in as 20-foot (SWL 32T, 36T) and 40-foot (SWL 40T) variants. The container spreader is equipped with high-quality components that are made of the best materials in the market, ensuring its long durability and reliability during its entire life span.

Please check out this video showing this spreader in operation: https://vimeo.com/460112319

Technical Specs:

-

-

- WLL 32T for the 20ft spreader

- WLL 40T for the 40ft spreader

- Customisable sizes available: 10ft and 45ft

- Safety landing pins

- Colour and logo upon customer request

- Gel batteries ready for Rough marine environments

- Min. IP66 components

- 2 sets of 2 Galvanised wire rope Slings

- Safety factor 1:5, EN-13414-1

-

Options:

-

-

- Long term Galvanized protection

- Forklift pockets (for empty use)

- Extension chains for damaged or deformed containers

- Switch to mechanical spreader if batteries run out

-

Contact our team today for a competitive pricing on our new BA-350E spreaders:

Easy Spreaders

- Ready for non-intensive use

- Suitable for all container types

- Available in indoor and outdoor versions

Spreaders for Indoor Use

- With short wires or directly linked to the hook of the crane

- Semi-automatic or manually operated

- For all kinds of containers

Our range of Optional Extras:

Forklift pockets

The best way to move and store the spreader when not in use. Pockets are only able to be used for transport of the spreader.

Security Pins

A useful addition to increase the security of the spreader. One pin beside each twist lock prevents the open movement of twist locks if the spreader is not fully connected with the container.

Guides / Flippers

Flippers facilitate approach maneuvers of the crane driver to the container. These can help to improve spreader productivity.

Galvanized

Galvanizing your spreader offers extra protection against corrosion. We use a hot dip galvanized coating, guaranteeing an extra long life.

Demountable for easy transport

Reduce transport costs and ship the spreader in a standard ISO container.

Extension Chains

Assist with handling open top or damaged containers. Different lengths available to suit your requirements.

Load Test Certificate

All our spreaders are delivered with a CE certificate. A third party inspection can be provided.

Extra Visible

Highly visible panels are an option – these help to inform the crane driver of the position of the cones.

Company Branding

All spreaders can be painted with your corporate colours and logo. A great branding opportunity for your organisation.

Our Spreaders Meet Safety Regulations:

UNE EN 13155 (Cranes, safety and cargo handling equipment)

- All twist locks are individually tested and marked

- User / maintenance guide included

- Periodical recommended check sheet included

- Both are provided in English or another language if you require

1. How many containers do you lift a day?

b) Less than 100 containers a day – Moderate use

c) Less than 10 times a day – Occasional use

2. What type of containers do you usually handle?

b) 20 ft ISO

c) 40 & 20 ft ISO

d) Different to above

3. What machinery do you use for lifting containers?

b) Mobile Harbour Crane

c) Ship to Shore Crane